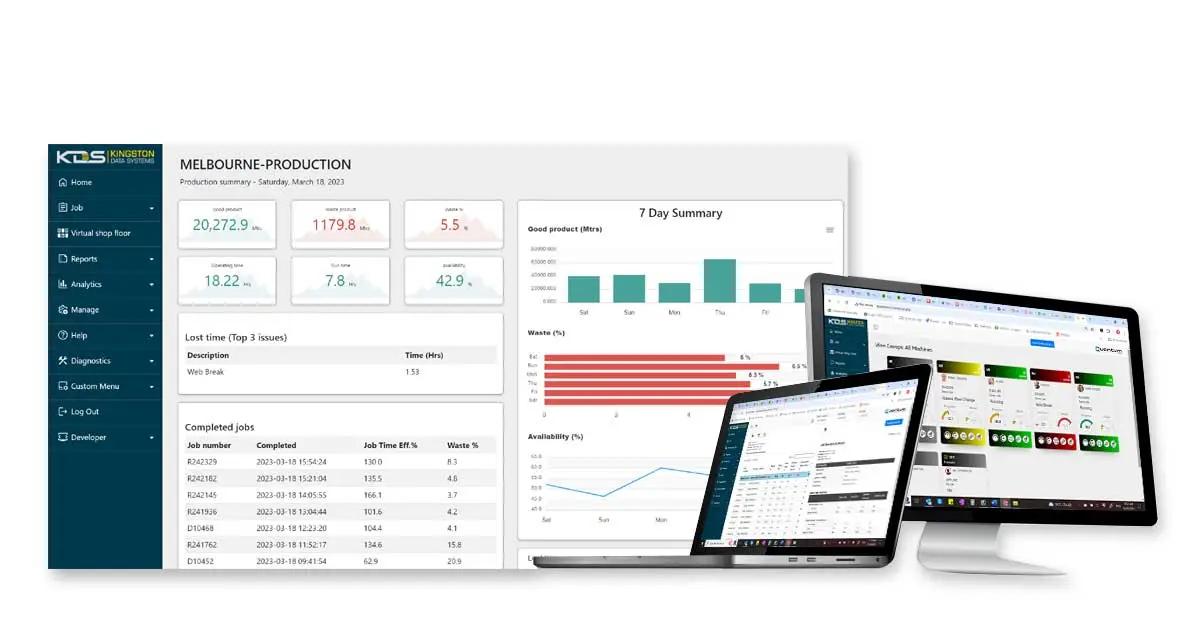

Our QUANTUM production monitoring software is helping companies around the globe to reduce waste, minimise downtime and achieve higher productivity.

Book a DemoEssential production monitoring software

Kingston Data Systems is the trusted partner for leading enterprises, SMEs, and forward-thinking companies worldwide.

Our Quantum Real-time Production Monitoring System provides unparalleled visibility into manufacturing operations, helping businesses track performance, detect inefficiencies, and make data-driven decisions.

By reducing waste, minimizing downtime, and optimizing production processes, we empower companies to enhance efficiency, improve product quality, and drive sustainable growth in an increasingly competitive industry.

Improve production performance and KPIs

Quantum is the ultimate, productivity boosting, production monitoring software that helps reduce waste, increase uptime and improve manufacturing efficiency.

Machine monitoring hardware

Efficiency Management Units (EMUs) are an integral part of our Quantum Production Monitoring System providing real-time monitoring of the production machines. They keep operators fully informed of production targets and real-time job progress, ensuring optimal efficiency and performance.

Manufacturing the Quantum Way

When customers demand the tightest tolerances in printed packaging, maintaining acceptable print quality can be a difficult task, especially on flexible films.

Accutrack print repeat length measurement and monitoring system has been specially designed to assist printers perform accurate online measurement and recording of print repeat length.

Take your Manufacturing to the Next Level